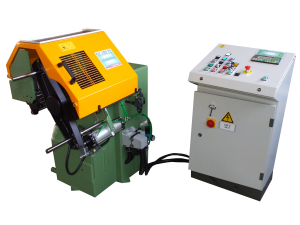

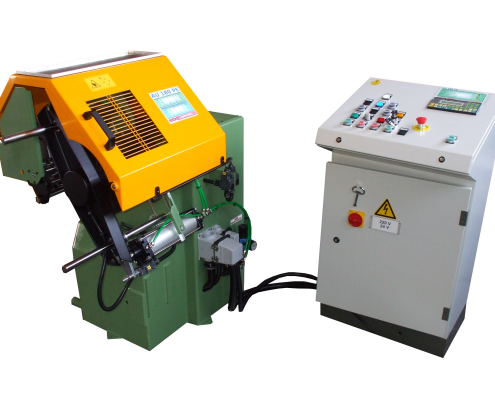

Coil winder AU180 : Turn to turn coil winder for ductile wire, with automatic ended coil extraction.

Coil Winder AU180

A simple to use machine for turn to turn winding of normal or coated ductile wires, annealed or galvanized plated iron, copper, zinc, aluminium, with diameters up to 5,0 mm.

It’s equipped with centesimal electronic adjustment of the wire guide pitch, simply by setting the desired pitch directly on a special keyboard. This system makes the machine extremely flexible and rapid for winding any diameter of wire with maximum precision (only for AU180SPE).

The windings stops when the desired numbers of coiled wire layers is reached, and already position for the next coil.

An automatic pneumatic system extracts from the winding drum the finished bound coil and carries it out for easy removal.

Possibility of replacing the winding drum with reels holder for Din 80-125-160-300.

The coil winder is combined with our unwinder – static decoiler model SV2 with capacity of 1.000 Kg, and it’s combined with our lubricating system on line model SLF01.

General Technical Specification

- Electronic adjustment system of wire-guide pitch in alternating current (only AU180SPE)

- Patented mechanical wire-guide carriage reversal system, with millimetric adjustment, in oil bath

- Front-sliding safety guard

- 8-12 Bar pneumatic supply with or without lubrication

- Self-braking master motor Kw 3 in alternating current

- Equipped with electronic speed adjustment up to 7 m/s with inverter

- Electronic coiled layer counter with pre-selection

- Electronic coils counter

- Separate electric box with push-button panel

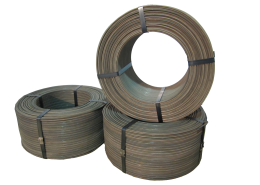

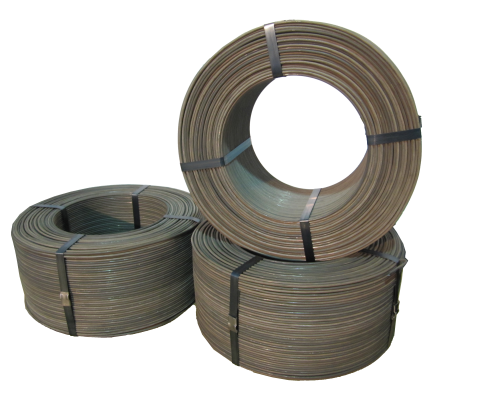

Coil Dimensions

- Standard internal coil diameter 200 mm

- Standard external coil diameter maximum 340 mm

- Standard coil width 150 mm

- Iron hoop hole 16 mm for 4 binding

Available additional options

- Decoiler model SV2 for Kg 1000 weight coils

- In-Line Lubricating System model SLF01